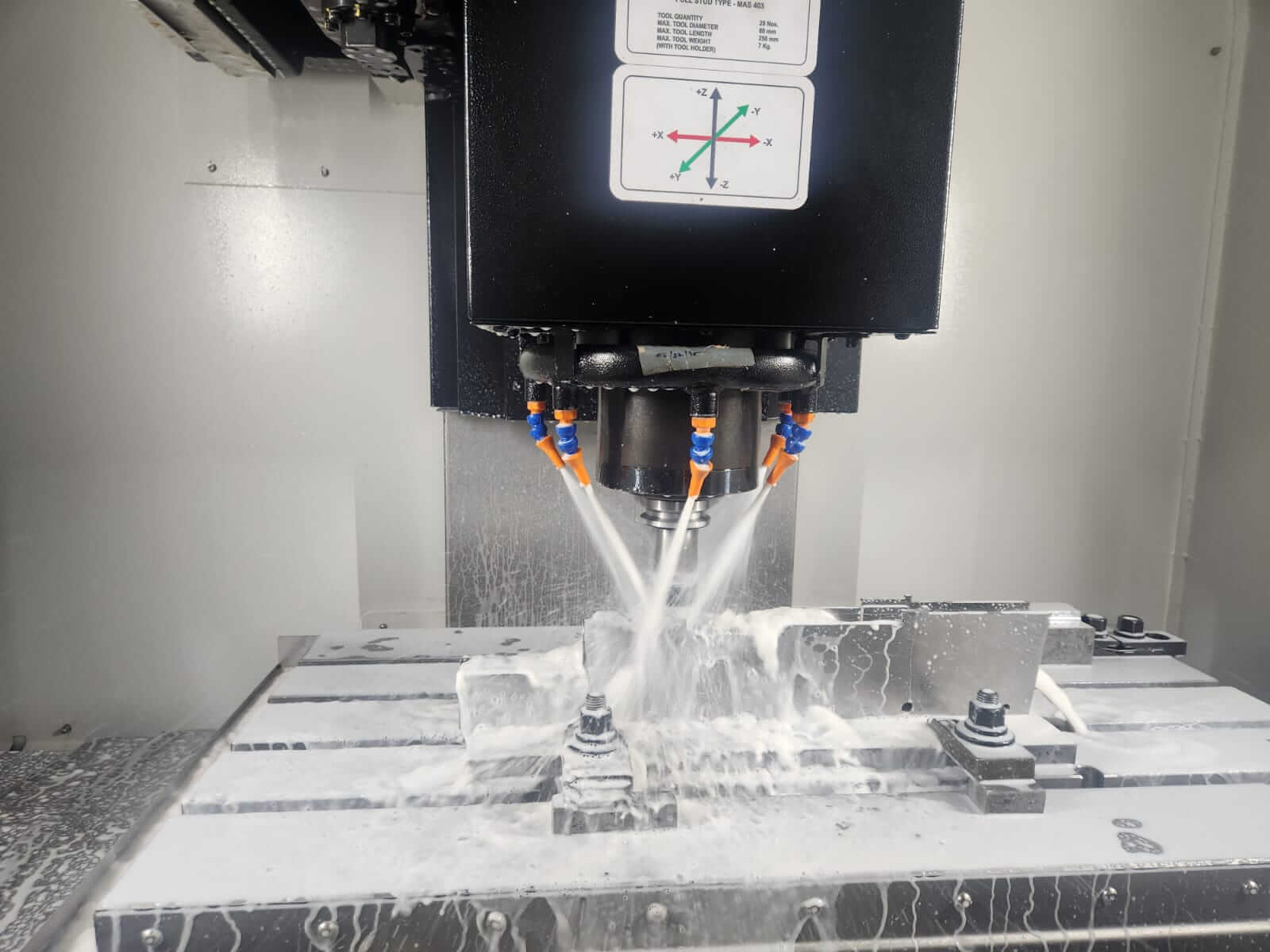

At AACK Technocraft, our infrastructure is designed to meet the highest standards of precision, quality, and reliability. Equipped with advanced CNC and conventional turning machines, vertical machining centers, cylindrical and surface grinding units, and EDM systems, our facility ensures we can handle complex geometries, tight tolerances, and diverse client requirements with accuracy. Every machine is maintained to peak efficiency, enabling us to manufacture high-performance components across sectors like defense, automotive, and industrial applications.

Beyond machining, we integrate welding capabilities (Arc, MIG, TIG), conventional milling setups, and specialized equipment such as automatic tapping machines and DRO systems to enhance production flexibility. Our infrastructure is further supported by outsourced finishing processes including heat treatment, wire cutting, friction welding, hard chrome plating, and nitriding — ensuring durability and reliability at every stage. With a skilled workforce and world-class infrastructure, we deliver consistent results that not only meet but exceed customer expectations, reinforcing our reputation as a trusted partner in precision engineering.

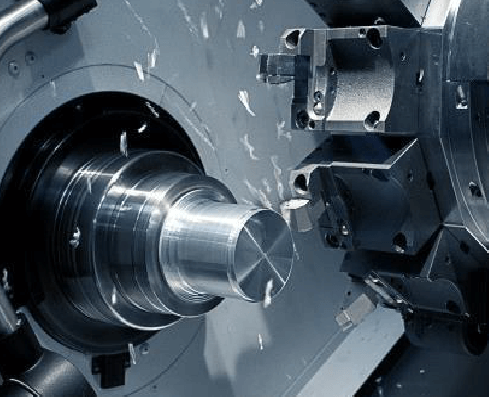

Our CNC turning facility delivers high-precision machining for complex cylindrical components, ensuring accuracy, consistency, and superior surface finish across diverse industrial applications.

Our conventional turning facility provides reliable machining solutions for medium to large components, ensuring flexibility and precision for diverse industrial needs.

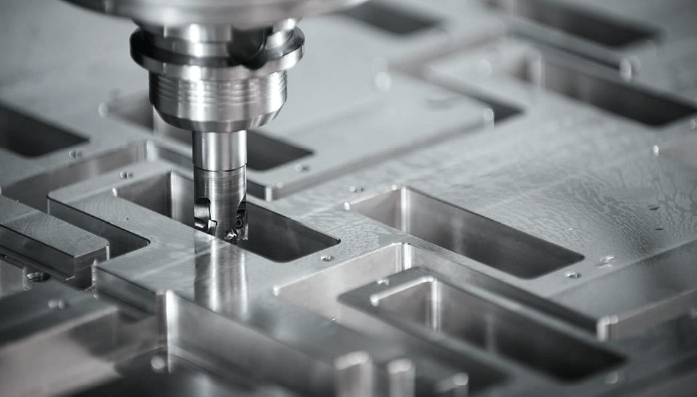

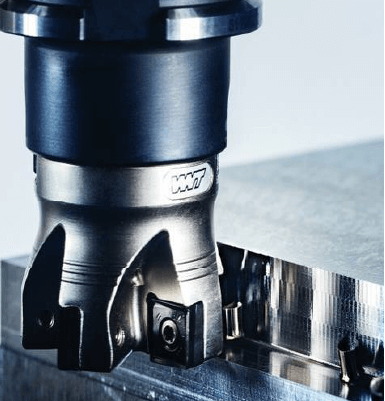

Equipped with advanced machining centers, we deliver high-precision milling, drilling, and complex component shaping with exceptional accuracy.

We specialize in high-precision cylindrical grinding, ensuring tight tolerances and smooth surface finishes for industrial-grade components.

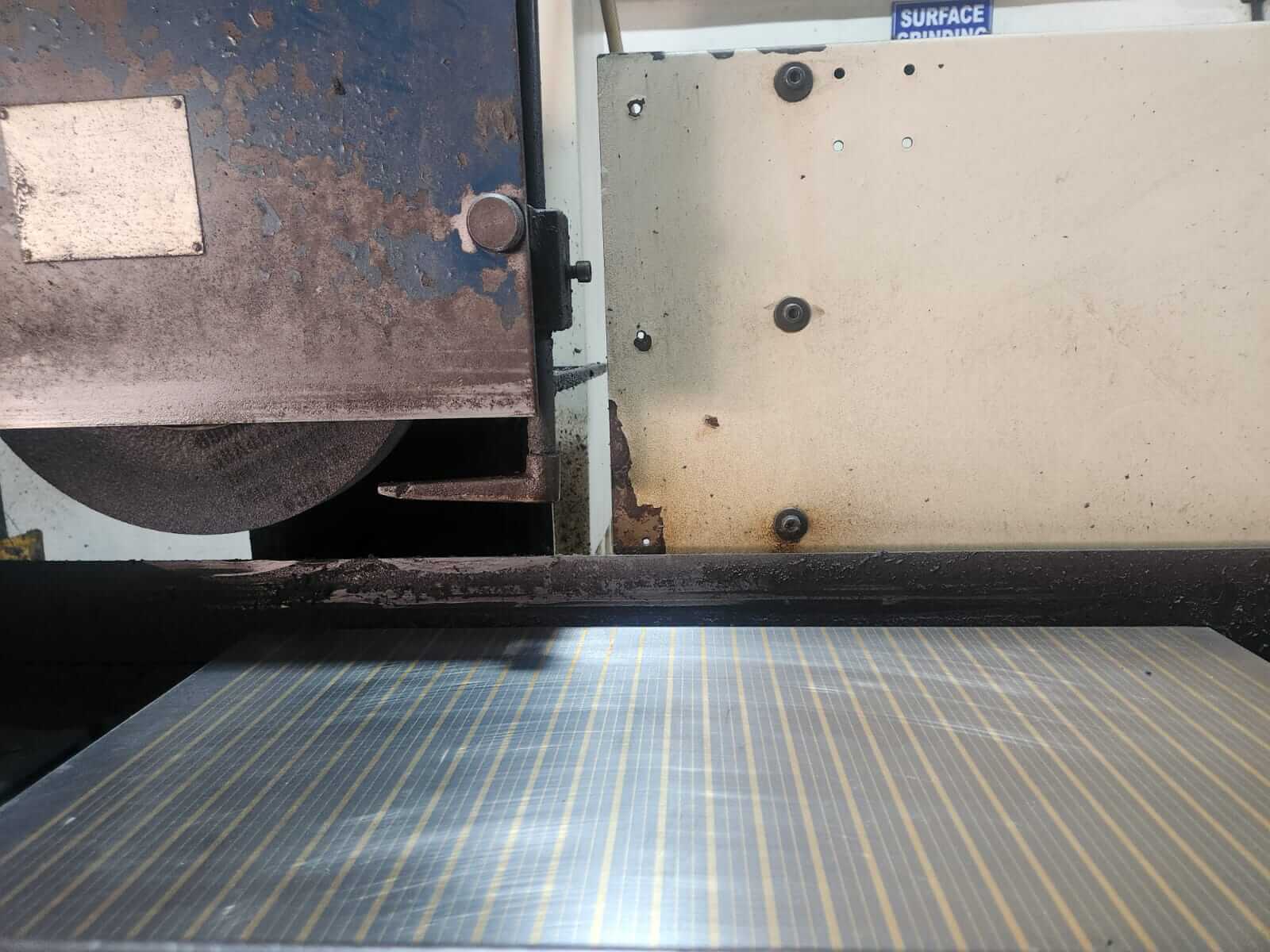

Our surface grinding facility guarantees high-accuracy flatness and smooth finishing for critical tooling and industrial parts.

Our milling infrastructure supports versatile machining for custom profiles, slots, and complex component designs.

We provide comprehensive welding services to meet the diverse joining requirements of industrial components and assemblies.

.jpeg)

Our EDM facility enables high-precision machining of intricate profiles, sharp corners, and hardened materials that are difficult to process with conventional methods.

Our tapping and DRO systems are designed to improve efficiency, accuracy, and repeatability in machining operations, ensuring faster production cycles and consistent quality.

To complement our in-house machining capabilities, we collaborate with trusted partners for specialized finishing processes. These outsourced treatments enhance material strength, improve wear resistance, and provide advanced surface finishes that meet the most demanding industry requirements.